Rule-Based, Real-Time Dispatching

EDDi is an automated dispatching system that provides sophisticated control over the evaluation of each unique dispatching scenario in your manufacturing environment. EDDi delivers constantly up-to-date, prioritized lot lists that equipment operators can rely on. Your equipment operators will always know the right lot to process, right now, on the right piece of equipment.

With EDDi, production floors achieve improved equipment utilization, maximum manufacturing capacity and reduced labor costs by consistently applying processing rules and automating lot-prioritization evaluation factors such as:

- Batching requirements

- Timer conditions

- Equipment capability

- Equipment availability

- Management priorities

Prepare to say goodbye to the headaches, spreadsheets, sticky notes and constant phone calls associated with manual dispatching solutions.

How does EDDi work?

Assigned factory personnel use EDDi’s Dispatcher Editor to configure EDDi to meet the unique needs of your production environment. Because the Dispatcher Editor is menu-based, configuration changes do not require IT support or software development. Configuration options include:

- Tool and operational relations

- Process capabilities

- Ordering schemes

- Ordering rules

- Inventory Ratio

- etc.

Once configured for your manufacturing environment, EDDi “listens” for lot and equipment events (such as “lot changed”, “equipment down”, "capability up“ etc.) that impact lot processing and immediately responds by updating dispatch lists.

As a lot “tracks in” at a given tool, EDDi updates the status of any affected lots on the list (and only the affected lot or lots), and at the appropriate time, removes the lot from all of the affected dispatch lists. Once the lot finishes processing on the equipment, the lot “tracks out” and is dispatched to the next step in the product’s flow, where it is inserted at the correct position within the tool(s) dispatch list at the downstream step. This cycle repeats until the lot is no longer in process.

EDDi delivers consistently up-to-date dispatch lists, prioritized based on your manufacturing requirements. The view of these always up-to-date dispatch lists, can be integrated into existing, customer-specific displays for the equipment operators. Alternatively, SYSTEMA also offers its own GUIs for the plant-specific lot lists.

Benefits

Visibility – Reduces mishandling of materials by providing visibility and enforcement of all timer conditions in all dispatch lists.

Automation – Allows equipment operators to focus on critical tasks by automating the communication processes required to keep WIP moving.

Compliance – Optimizes production by measuring how closely equipment operators are following dispatch list recommendations. Operator identification is associated with lot dispatching actions.

Efficiency – Avoids quality issues and saves time by providing dispatch lists where only the lots that are capable of being processed on a piece of equipment are available for selection by the equipment operator.

Transparency – Provides a dispatch list for each tool for all lots in queue, giving equipment operators constantly up-to-date proposals for the right lot to process, right now, on the right piece of equipment. Within seconds of any event, affected lots are instantly re-evaluated and, if necessary, automatically repositioned within the dispatch lists.

Architecture

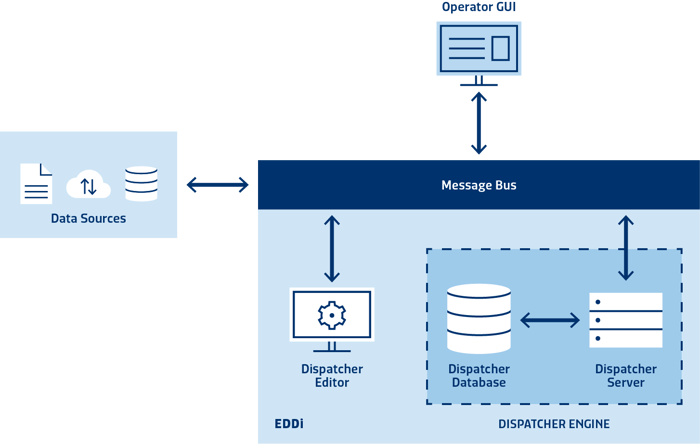

EDDi’s system architecture is key to the efficient way it communicates with manufacturing data sources in order to provide real-time prioritized lot lists to equipment operators.

Core Components

EDDi has two components: the Dispatcher Editor (for configuration) and the Dispatcher Engine (for storing/calculating dispatch lists). These components, along with all other manufacturing data sources and an MES, are connected to message-oriented middleware (aka a message bus). This middleware layer allows for communication among all integrated components/data sources and EDDi.

Data Sources

EDDi can process data from any source that is able to publish events on the bus. EDDi also integrates into a variety of MES and CIM environments, including eyelit®, WorkStream®, PROMIS®, and SAP-ME.

The following are the typical data sources that the dispatcher works with:

- Manufacturing Execution System (MES)

- Material Control Systems (MCS) or Automated Material Handling Systems (AMHS)

- Recipe Management Systems (RMS)

- Equipment Automation

- Out-of-Control Action Plan (OCAP)

- Databases

- Files

- Cloud data

For more detailed Information view the EDDi Data Sheet.

Implementation Process

SYSTEMA’s Approach

SYSTEMA goes beyond providing software licensing. We are solutions consultants who partner with and advise our clients as they explore the art of automation. We begin by gaining a comprehensive understanding of your business. During on-site workshops, working together we will identify, gather, and prioritize requirements, determine ROI, formulate KPIs, and align the vision and objectives with stakeholders (management, production, IT, enterprise management, etc.) From there, we typically strive to first develop and provide a proof-of-concept as a basis for further iteration and development into a final product for testing and future deployment. Our team is present in the EU, US, India, SEA, and Brazil, and we are prepared to support your initiatives, large and small, to efficiently realize the benefits of a Digital Transformation of Manufacturing.

Licensing

EDDi is offered as a licensed software product, configured and run on-premise, with options for maintenance and support contracts based upon individual factory needs.

SYSTEMA provides training, and, if needed, services to deliver a fully functional dispatching solution that is integrated with a manufacturing environment’s existing IT systems, including integration with the MES shop-floor user interface (UI), or SYSTEMA’s shop-floor UI for dispatching. Turnkey projects typically take 4 to 8 weeks for “first dispatch lists” and range from 3 to 12 months duration for complete rollout, depending on the complexity of the existing IT infrastructure, and operational and manufacturing processes.

For additional information, or if you would like to schedule a demo or a workshop to discuss your real-world dispatching needs, please contact us and we will follow up with you directly.